- Joined

- Feb 7, 2009

- Messages

- 12,531

- Reaction score

- 1,176

- Points

- 113

- Location

- Cape Coral, Florida, USA

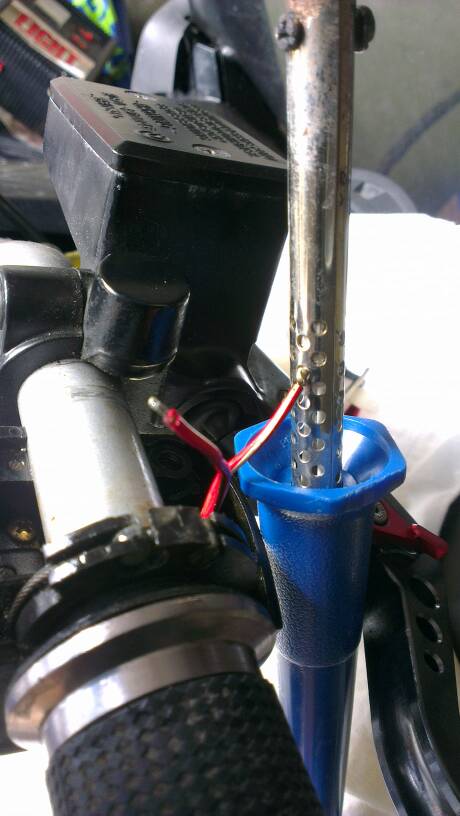

I wasn't going to leave a hole lol, I was thinking that I might have to remove the actual switch and possibly make a blank for the hole.

Neil

With all the bikes being parted out, I'd hot wire it for now, and look for a used switch if you like having/using it.. Just a thought :thumbup: