AdamFZ

Junior Member

ADDITIONAL TESTING:

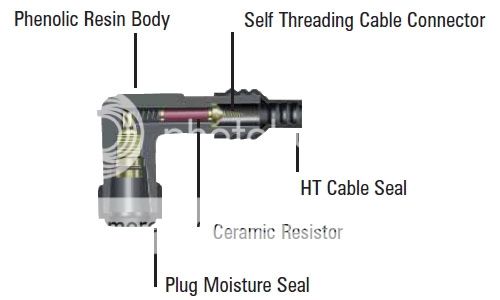

The SPC is composed of several parts which should be verified by testing and visual inspection during spark plug replacement or if they are suspect of causing a misfire or vibration. Because these connections are subject to high voltage (15,000+ volts) bad connections can burn and arc damaging components.

With an ohm meter set to K ohms, insert the test leads into each end of the cap. It should measure 10K ohms. Internal to the cap is a resistor, spring, plug lock, and self threading cable connector. If any of these component have corrosion, arcing, or burning, they should be replaced. Also, the FSM does not list a limit. Mine all measured 10.7 ~ 10.8K ohms.

The resistor spark plugs are supposed to measure 5.0K ohms. My used CR9EK's measured ~ 4.0K ohms each.

I've just measured my caps and 2 were 10.5k and 1 was 9.3k and one was 8.4k, is it worth replacing the lower 2 ?

Last edited: