RJ2112

Junior Member

- Joined

- Mar 25, 2009

- Messages

- 2,108

- Reaction score

- 23

- Points

- 0

- Location

- Dahlgren, VA/USA

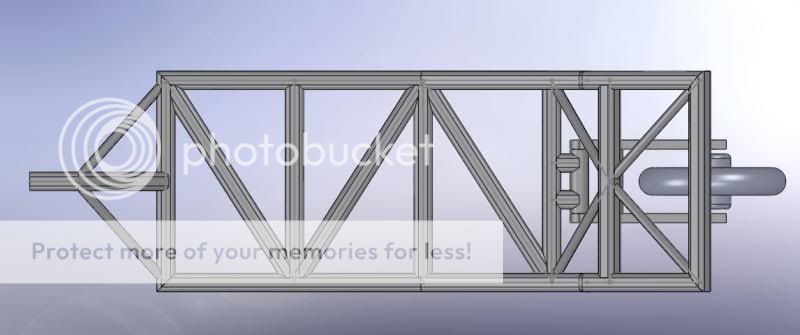

My 2 cents, How would 150lbs pushing on the rear of the bike affect braking? I know it is a concern with pulling car trailers but smaller boat trailers have no adtional breaking system.

150lbs is @1/4 of the bike weight. I'd worry about jackknifing. May be way off but wanted to throw that out there JIC.

If the rider weighs 150 and has a 150 lb passenger, and 40 lbs of luggage on board, it's not so bad... I'm betting the braking system as installed is designed around at least that much of a combined vehicle weight.

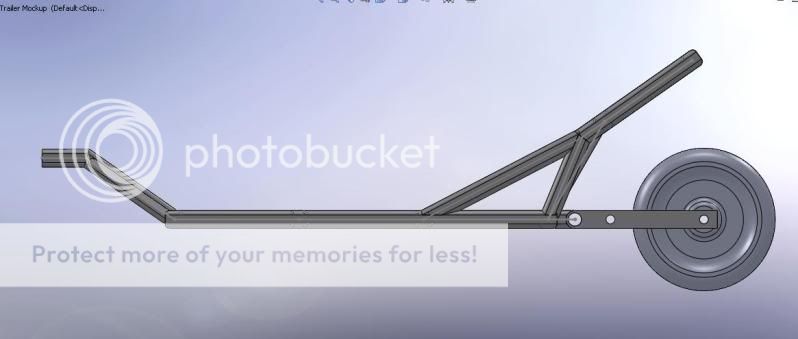

My guess would be that it's very important how the tongue of the trailer is going to 'push' the chassis.... if it pushes the rear 'up' as you decellerate, could it unload the rear tire? If it pushed down, what would that do to chassis attitude?

I would personally want the force to pass as nearly as possible through the center of mass....